- info@perpetualpack.com

- +61-7-3186-1044 AUS

- Call Us Today

Menu

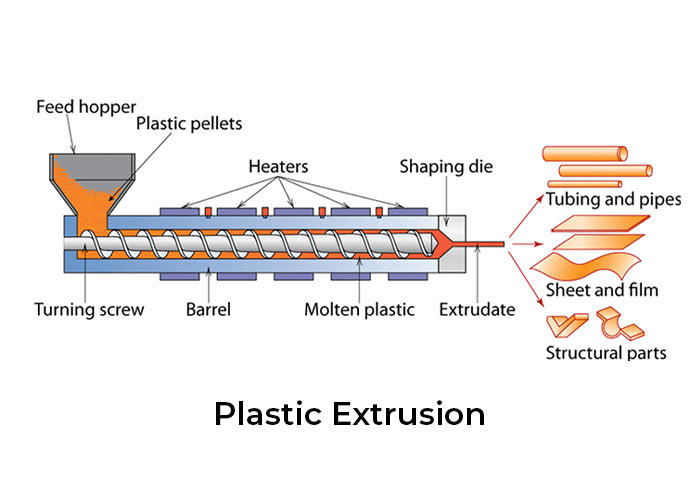

Plastic extrusion is a high-volume manufacturing process where raw plastic is melted and formed into a continuous linear two-dimensional shape. This differs from other methods whereby manufacturers push melted plastic through a die to make continuous lengths with the cross section of the die. The shape of the die will determine the shape of the tube. Once it cools the plastic can take the form of a length linear tub or piece that can then be cut into different lengths.

Various products such as pipes, tubes, window frames, doors etc are manufactured by using this technique.