-

+61-7-3186-1044

-

info@perpetualpack.com

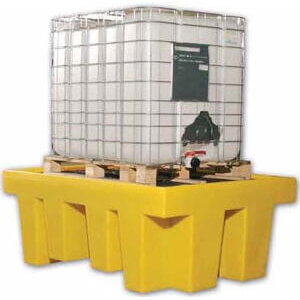

Liquid Bins- IBCs Container

Bulk liquid storage

When it comes to storing liquids in large quantities, industries across a wide range of sectors rely on the efficiency and flexibility offered by liquid bins or intermediate bulk containers (IBCs). These robust containers have become an essential part of many industrial operations due to their versatility and ability to store various types of liquids.

One of the primary advantages of using a liquid container is their large storage capacity. With the ability to hold up to several thousand liters of liquid, they make it feasible to store bulk quantities without the need for multiple smaller containers. This not only streamlines storage but also minimizes the footprint required for liquid storage.

Furthermore, liquid containers are designed to handle a broad range of liquids – from hazardous chemicals to food products. They are made from durable materials such as high-density polyethylene (HDPE) or stainless steel, ensuring compatibility with a wide variety of liquids. Their robust construction prevents leaks, contamination, or any unwanted interaction between the stored liquid and the container itself.

Another advantage of using liquid containers is their transportation efficiency. These containers are often equipped with sturdy handles, allowing for easy maneuverability within industrial settings. Moreover, their shape and size are designed to fit well in standard transportation modes such as trucks, railways, or shipping containers, optimizing logistics and minimizing the risk of damage during transit.

Intermediate bulk containers – IBC Containers

Intermediate bulk containers, commonly known as IBCs container, have gained immense popularity across industries due to their superior functionality and adaptability in handling liquids.

One of the key features that make a IBCs container favorable in the industry is their modularity. These containers are typically composed of a metal cage or plastic frame surrounding an inner container – a bladder or bottle. The modular design allows for easy disassembly, cleaning, and replacement of damaged parts, making them highly economical and sustainable in the long run.

IBCs container offer a multitude of benefits compared to traditional storage methods. Firstly, they minimize the risk of spills, leaks, or contamination, as they are equipped with secure closures and high-quality materials. This is particularly crucial when dealing with hazardous substances or sensitive liquids that need to be stored and transported safely.

Additionally, the versatility of a IBCs container is undeniable. They can be designed with various features to accommodate specific industry needs. For instance, some IBCs are equipped with heating or cooling systems to maintain the ideal temperature for a particular liquid. Others have advanced valves, pumps, or mixers, enabling efficient dispensing or blending of liquids on-site.

Moreover, IBCs provide a cost-effective solution for industries that require frequent product changes or small batch production. Instead of investing in large-scale storage tanks or silos, which may be excessive for their needs, businesses can opt for IBCs that offer the required storage capacity without excessive costs or wasted space.

In conclusion, liquid bins or IBC containers have revolutionized the way industries approach liquid storage. With their exceptional versatility, robustness, and transport efficiency, these containers have become an indispensable asset across various sectors. Whether it’s the pharmaceutical, chemical, food, or manufacturing industry, IBC containers play a vital role in ensuring safe, reliable, and efficient liquid storage and transport.